Total Manufacturing Solution For Plastic, Rubber Molds, And Parts

One-Stop Destination For Top-Quality Injection Molding

Our services encompass a variety of offerings within the realm of manufacturing and fabrication.

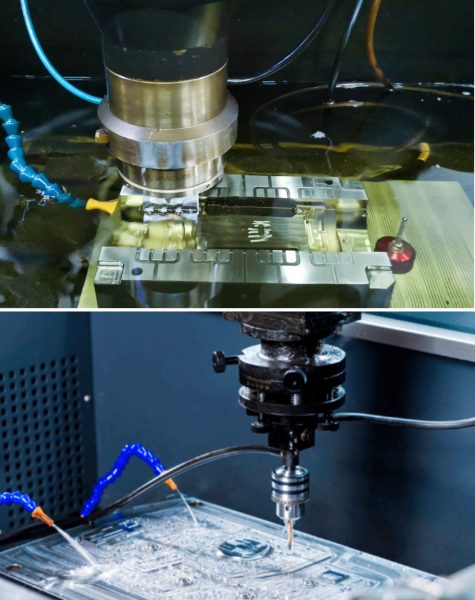

Precision Mold Design And Manufacture

Our Mold Technology Team Comprises Dozens Of Seasoned Engineers, Each Wielding Over 20 Years Of Expertise. Their Mastery Ensures...

Learn More

Over Molding & Insert Over Molding Technology

Over molding is an injection molding process used to mold one plastic (commonly a rubber-like plastic called TPE) over...

Learn More

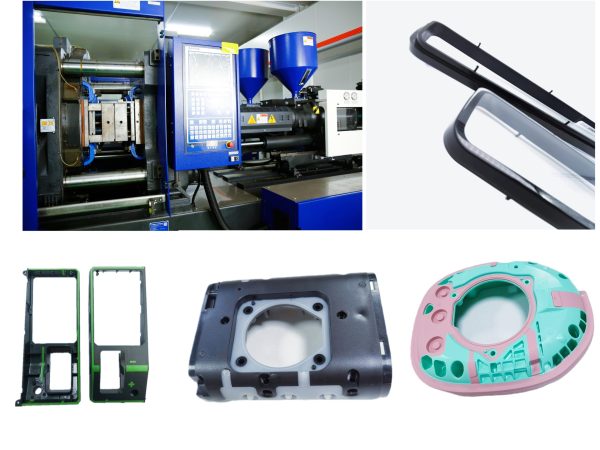

Double Injection Molding /2K- Shots Molding Technology

Double injection molding is a plastic molding solution that two different materials or same material with different color are...

Learn More

Full/Semi assembly and IP-level waterproof solution

Our research and development team can provide a complete solution for all the waterproofing products. They can also provide...

Learn MoreInjection molded parts and Liquid Silicone Rubber Experts

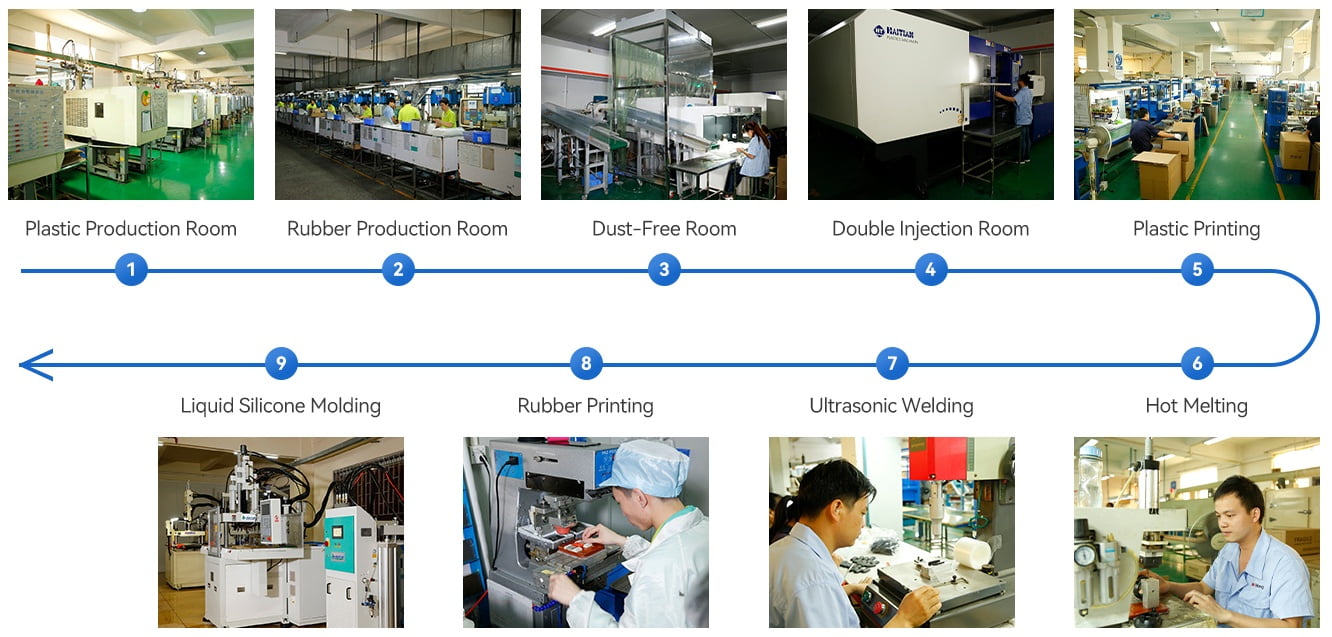

Almost 90% of our productions have been transformed to be automatic production with robots.Our highly professional production team uses...

Learn More

Optical, Sensor, Fresnel design and manufacture specialist

Home Technical Advantage Specialist in Optical, Sensor, And Fresnel Design Specialist in Optical, Sensor, And Fresnel Design Rilong is...

Learn MoreAbout us

Since 1990, Rilong Precision Mold has excelled in crafting plastic and silicone rubber molds and products. Our top-tier mold engineering expertise ensures optimal designs and high manufacturing standards. Our in-house advanced equipment guarantees precision and flawless surfaces. With a robust quality control system, we confidently serve customers, prioritizing their satisfaction. The key factor in helping us to maintain excellent quality is the use of ISO9001, ISO14001, and IATF16949 throughout all of our business, our factory has been awarded the UL-approved factory, and we carry out 6S management system in our factory.

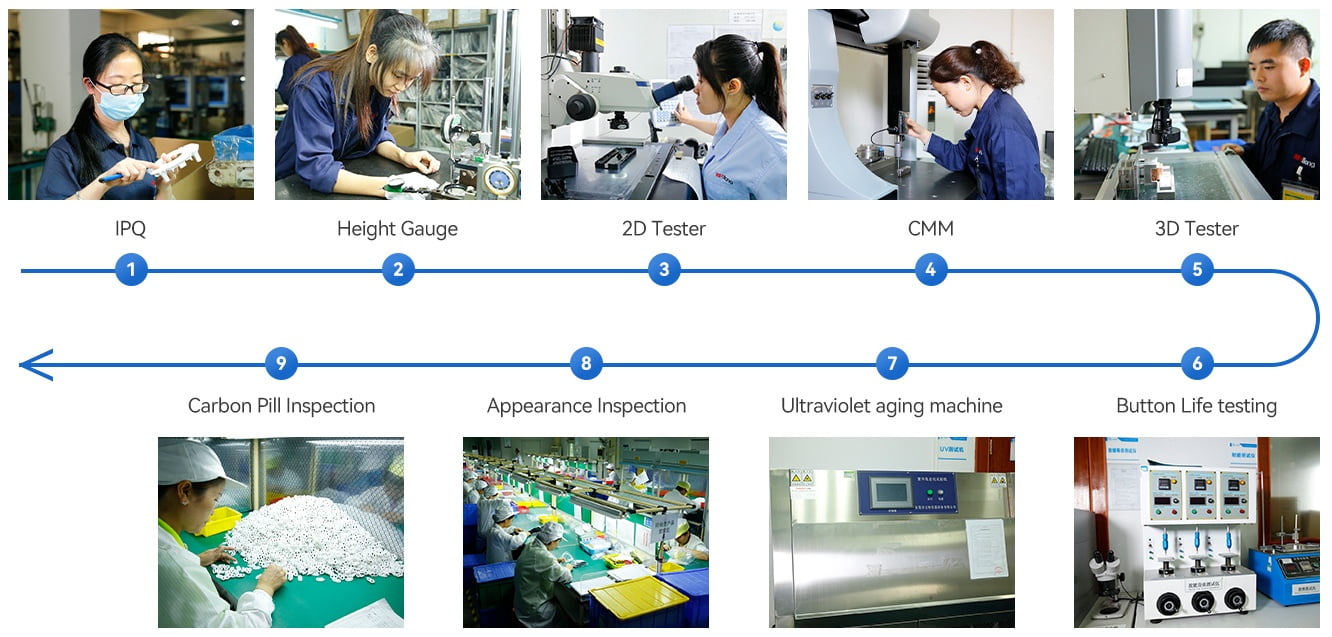

Project Flow Chart

Define the Product

Our product designer team will work closely with you to define the product design specifications.

Project Plan

A project plan outlines the scope, tasks, timeline, resources, responsibilities, risks, stakeholder communication, review points, and budget

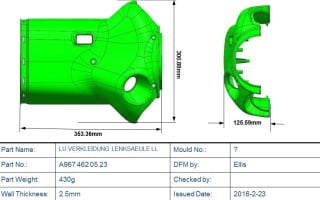

DFM Report

A DFM report assesses a product's design for efficient, cost-effective manufacturing, analyzing process, material, geometry, tolerances, and costs.

Mold 2D/3D Design

Mold 2D/3D Design involves creating, simulating, and testing a mold design using CAD software for efficient and accurate manufacturing.

Customer Approval of Mould Design

The Customer Approval of Mould Design stage involves customer review and approval of the mold design before manufacturing begins.

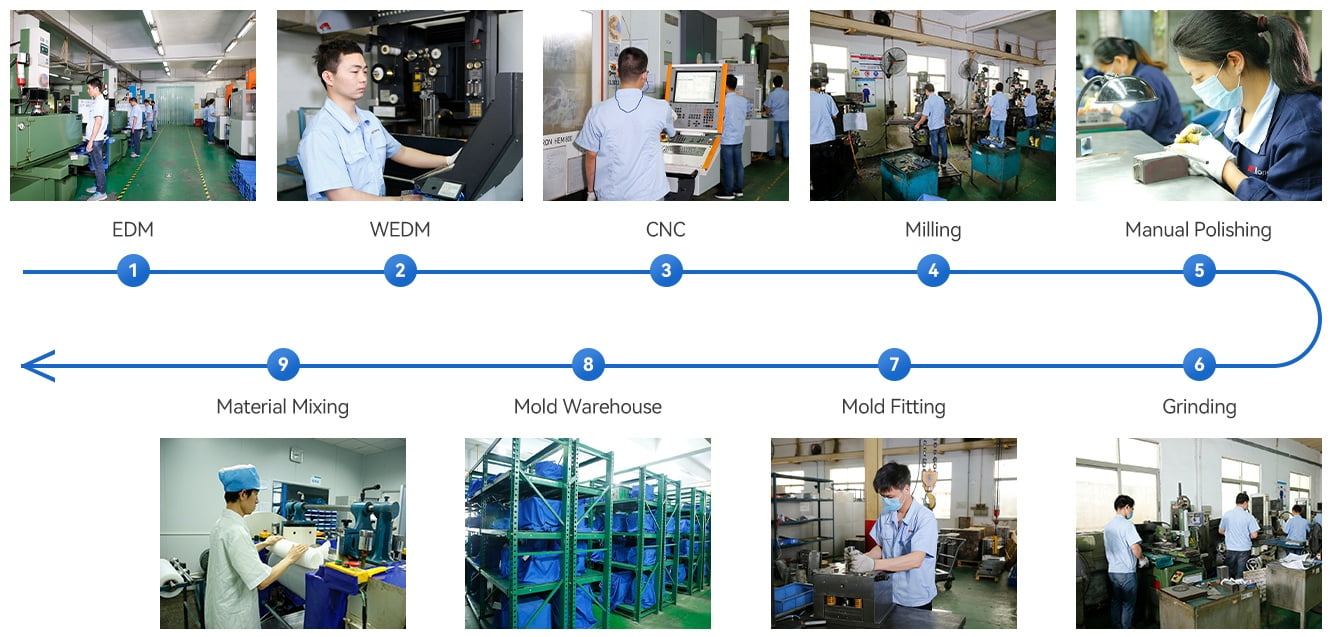

Mould Production

Mold Production involves mold design, material selection, machining, assembly, and testing for mass production

Mould Trial

The Mould Trial tests injection molds, producing and inspecting parts to ensure design specifications and quality before full-scale production.

Sample Inspection

Sample Inspection involves examining prototypes and initial production samples for design accuracy, quality control, and continuous improvement.

Customer Approval of Sample

The Customer Approval stage involves prototype presentation, customer review, feedback and revisions, and final approval.

Mould Delivery

Mould Delivery involves mold packing and delivery.

Trusted for manufacturing by

With over 30 years of manufacturing experience

Let's Make Cool Things Happen

Contact Us

Phone: +86 183-0011-5585

Visit Us

Electronica 2024, Munich | November 12-15.

RiLong showroom at Hall C6, Booth 141-7.

Our Socials

Bring your product idea to life in as soon as 5 days!