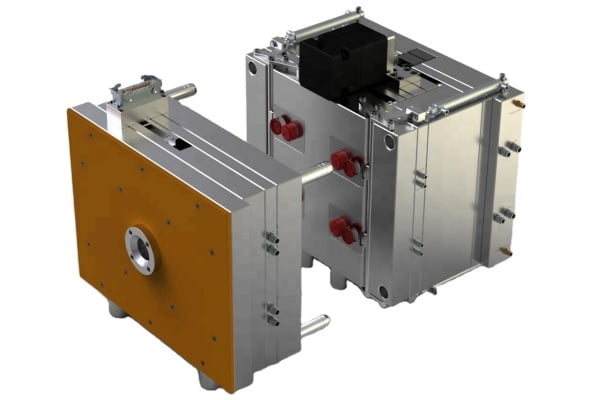

Since 1990, specialized in the design, Innovation, Engineering, and Manufacturing of OEM plastic, Silicone Rubber, Injection, Compression, Liquid Silicone Rubber, 2K, and Overmold.

Since 1990, specialized in the design, Innovation, Engineering, and Manufacturing of OEM plastic, Silicone Rubber, Injection, Compression, Liquid Silicone Rubber, 2K, and Overmold.

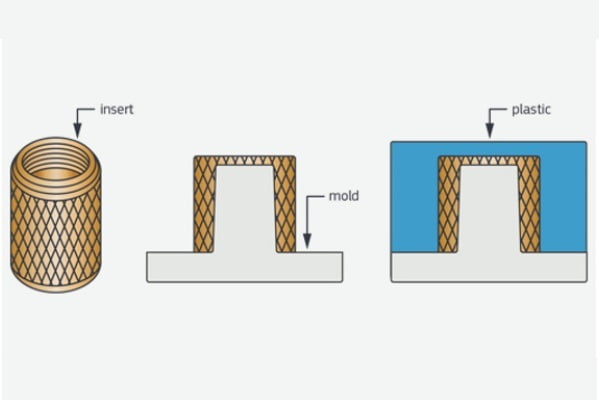

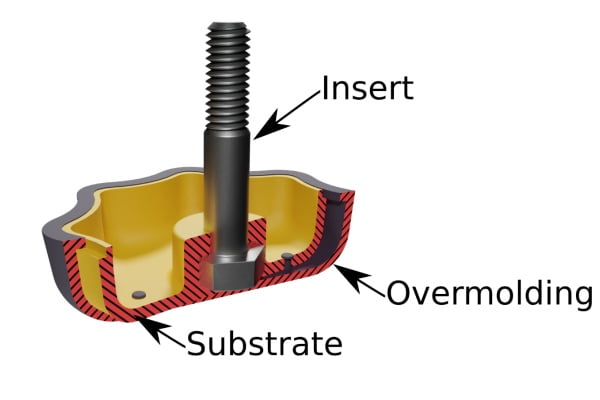

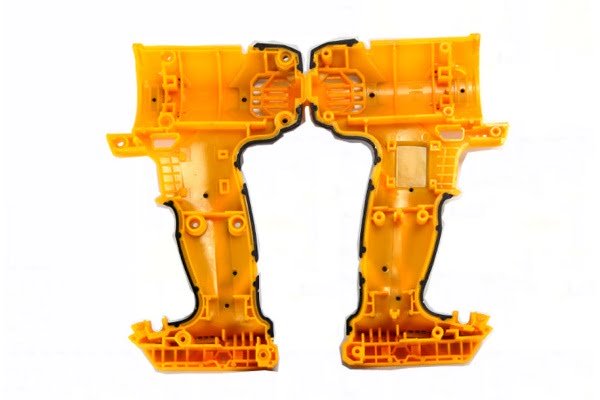

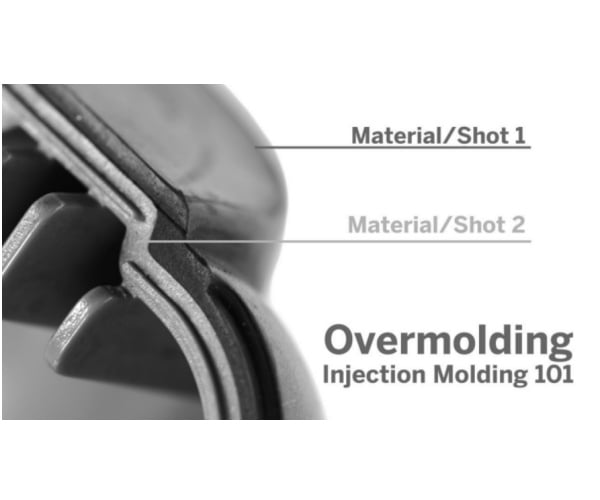

Over molding is an injection molding process used to mold one plastic (commonly a rubber-like plastic called TPE) over top of another component (substrate). The substrate is usually an injection-molded plastic part, but it could also be made from various other materials, like rubber, metal piece, SS or brass screw inserts, cables, etc. Overmolding can be used to combine similar materials of a different color or to combine materials for functional purposes, such as giving a product a soft grip.

Over molding has many benefits over the traditional assembly processes and can provide products with:

●Better adhesion between components

●More compact design

●Lower labor costs during production

●Noise and vibration reduction

●Protection from UV and corrosive chemicals

●Waterproofing

●Electrical insulation

However, these advantages come with a cost. They require a more complex and expensive mold setup process for manufacturing. With that said, over-molding is often reserved for specialty parts and high-volume production.

We have a wide variety of over-molding technologies and sealing solutions. Our professional technical team can solve the technical needs and engineering problems of various types of customers.

● Plastic over-molding with plastic

● Soft plastic over-molding

● Silicon rubber over-molding

● Silicone rubber and plastic over-molding

● Soft and hard plastic over-molding with metal parts

● Soft plastic or silicone rubber over-molding with electronic components

● Plastic over-molding with silicone rubber seals

●We can design and manufacture various types of molds requiring over-molding processes