The Rilong Precision Mold Story + History

We have been developing mold-making services and products that are affordable, reliable, and robust.

Pioneering Excellence and Growth!

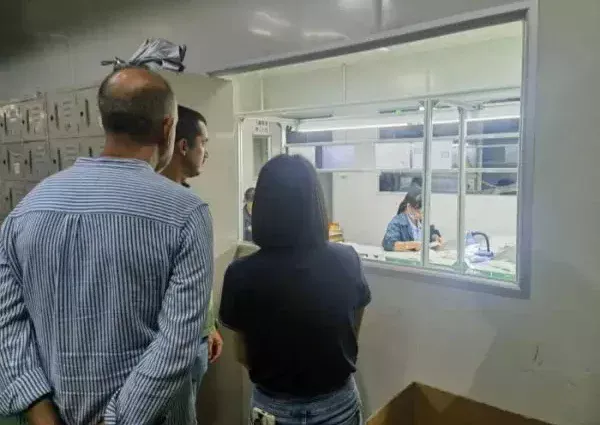

Rilong Precision Mould is located in Shenzhen, Guangdong, China. Established in 1990, and covering 11,000 square meters, Rilong has been offering mold-making services for clients around the world.

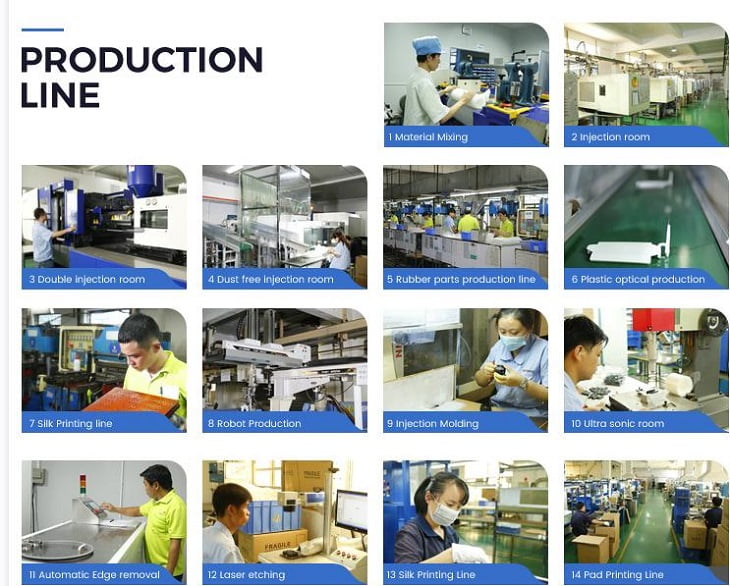

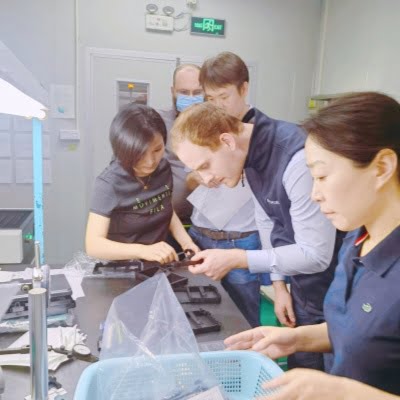

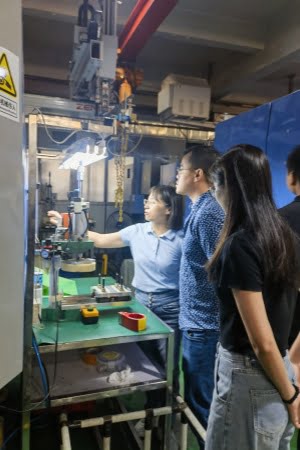

With a decade of cumulative experience, continuous improvements, and substantial growth since our establishment, RiLong expanded its facilities in 2000. Our capabilities span the in-house manufacturing of plastic molds and injection parts. Currently, our workforce comprises 300 skilled and experienced members dedicated to engineering, production, inspection, and quality control units. Our comprehensive services extend seamlessly to final assembly, covering screen/pad printing, spraying, laser etching, hot melting, insert molding, packing, and full assembly. All these intricate processes are flawlessly executed within our state-of-the-art facilities.

Delivering Innovation Since Inception Years

01

Close Collaboration

02

Cutting-Edge Equipment

03

Expertise And Experience

04

Stringent Quality Control

We Give Life To Your Ideas

Everything is designed, few things are designed better with our products.

Our Story

It all started with a bold idea pitched by our founder Boshan Zhang. Since then, it all has been about developing high-precision molds!

The Mould Industry Association

Honorably elected as Council Member company of Shenzhen Die&

August 2003The New House

We set up our rubber house in Dongguan with a land size of 8000 sqm. currently employs 120 workers, we can offer customers all kinds of rubber keypads, gaskets, covers and others from initial design to final product.

June 2006Certification

We've attained ISO 9001 Quality System and ISO 14001 Environmental Management system certifications, alongside securing UL certification for our products. Furthermore, we've earned IATF16949 certification for the production of plastic and rubber auto parts.

October 2008University Partnership

We established a long-term partnership with the Hong Kong Polytechnic University for optical, fresnel, and light guide parts production.

October 2015Total Project Solutions

We signed long-term partnerships with our sub-contractors to provide customers with ONE-STOP service for an entire project, including die casting, cable assembly, PCB&assembly, and Packaging.

October 2020Frequently Asked Questions

10 samples will be provided for each mold test free of charge. (FREIGHT COLLECT)

1st: after the order is confirmed, we will provide the tool DFM. material data sheet or other specifications for customer confirmation within 2-3 working days.

2nd: and then tool structure drawing is provided for final approval after DFM is Closed, normally 3-4 working days. If there is a hot runner system/controller. we will be providing the. design of the Hot runner system/controllers provided by Yudo for your approval within 2-3 working days.

3rd: As long as the tool model is approved, we will start mold steel purchasing and arranging the mold processing, lead time for completing one full mold and trials will be at least 25-30 days, depending on the mold structure, we will provide the mold schedule form for your synchronous follow up).

4th: After the mold is finished, we will conduct our internal mold trials and inspection, then send out the first article samples without the surface treatment for checking structure, assembly function, etc by the customer. Until the structure has been confirmed, we will go to finish the mold surface treatment, in case there might be any changes to cause any damage to the surface.

5th: Lastly. A small lot trial will be suggested before the molds are transferred back, to make sure all the parameters run normally and are stable.

Our Partners

Bring your product idea to life in as soon as 5 days!