Specialist in Optical, Sensor, And Fresnel Design

Rilong is an esteemed specialist in Optical, Sensor, and Fresnel design and manufacturing, crafting cutting-edge devices, sensors, and precision lenses.

Our commitment to innovation ensures high-quality solutions for diverse industries, excelling in optical tech and sensor innovations.

Here are our core technologies in the manufacturing capabilities of Mobile Detectors, Intrusion Alarms, and Human Presence Sensors:

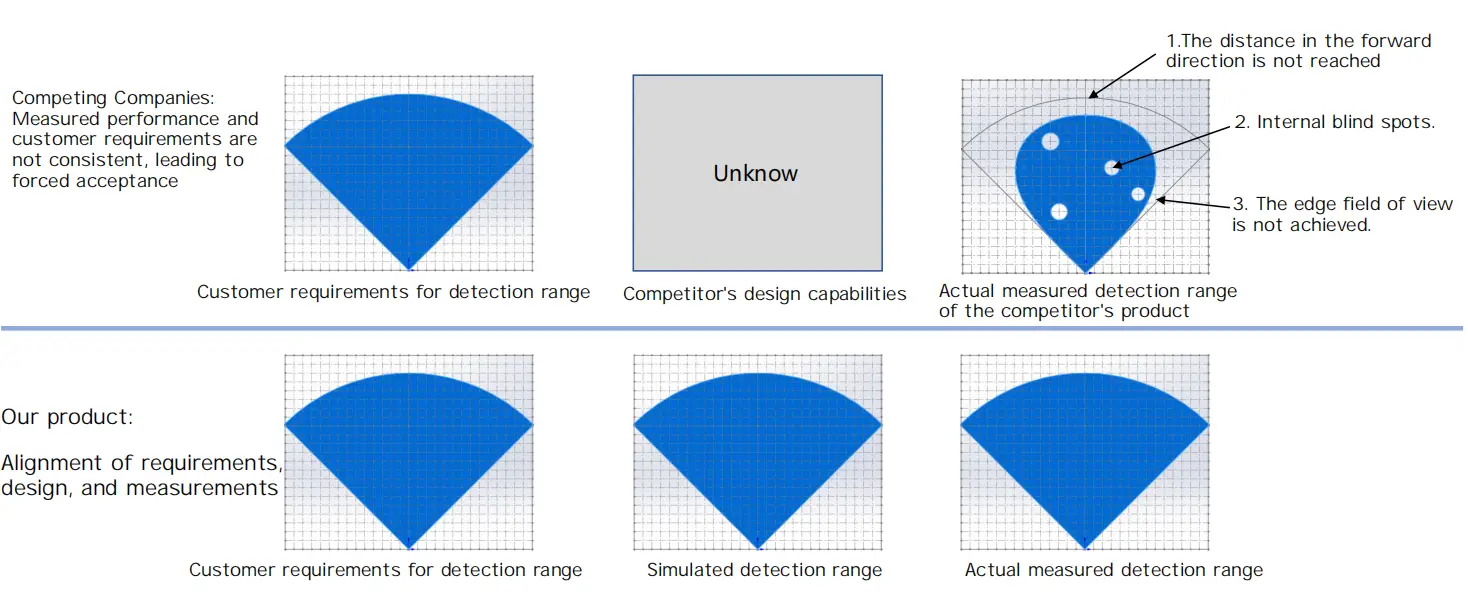

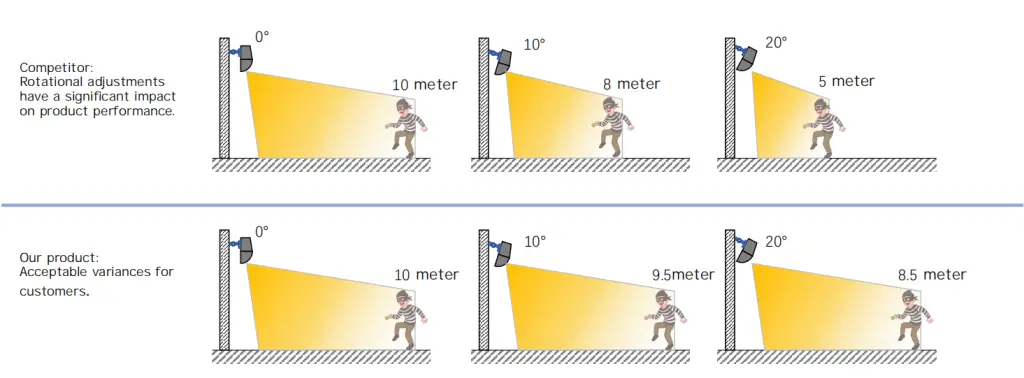

2. Under the same conditions, the performance of the product is better than the competitors, exceeding more than 30%.

3. The product has good adaptability to installation and adjustment, and can cope with a variety of installation environments.

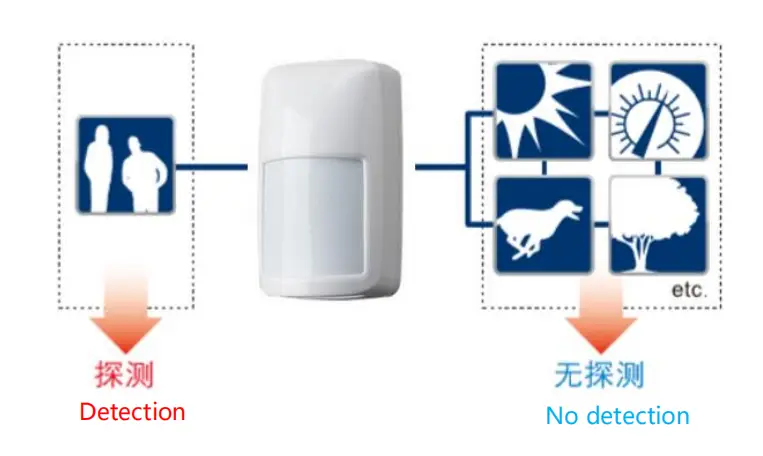

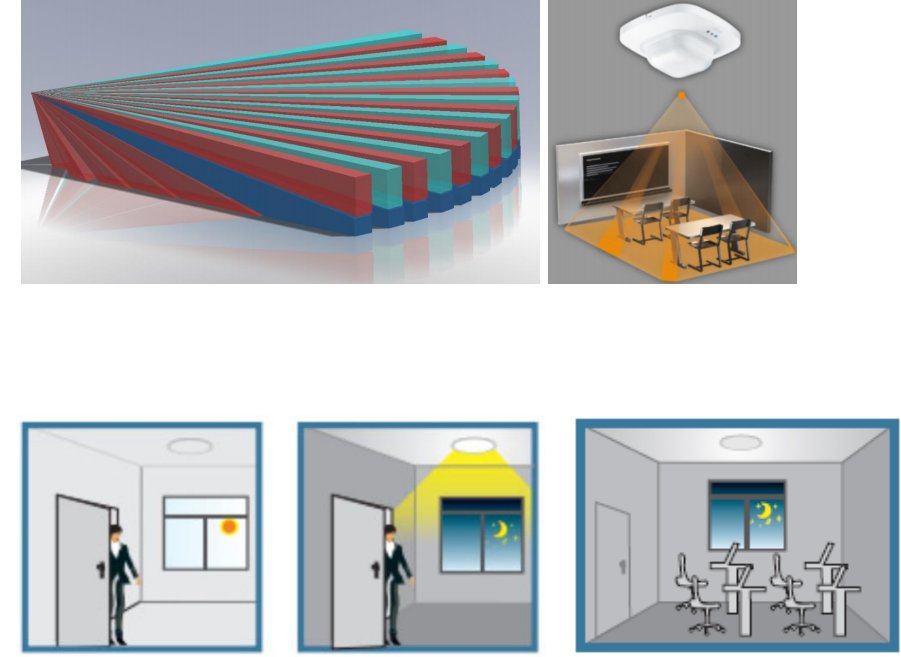

5. We are the only team that can provide safety level, intelligent control level, and human presence detection level PIR technology.

6. Combined with PIR intelligence and energy-saving control, 15cm human presence detection is realized to meet wider needs.

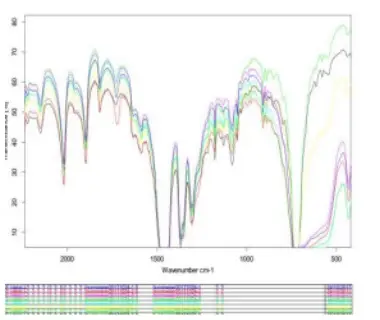

7. Use unique materials to ensure product performance and batch stability, and improve customer satisfaction.

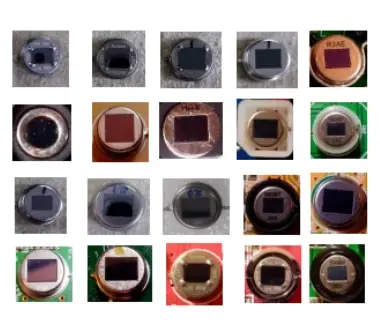

8. A thorough analysis of nearly 100 sensors, including PKL, NICERA, MuRata, Maier, Senba, etc.

8. A thorough analysis of nearly 100 sensors, including PKL, NICERA, MuRata, Maier, Senba, etc.

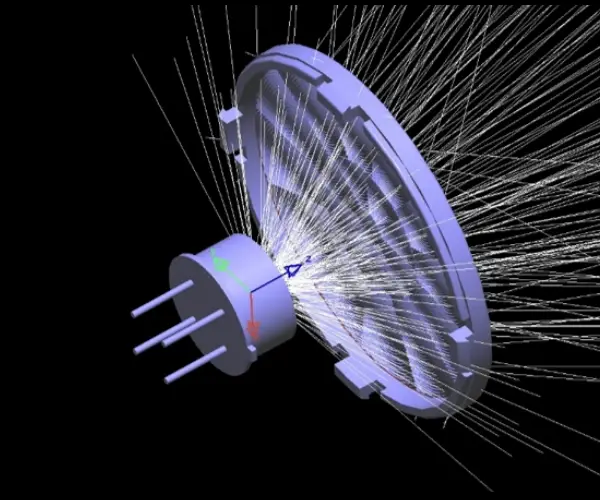

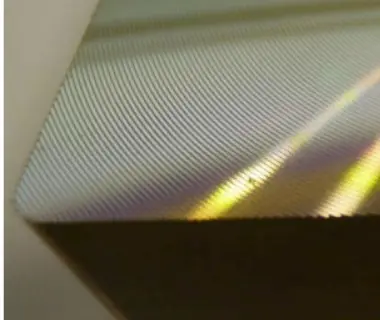

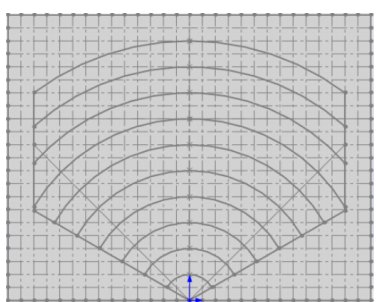

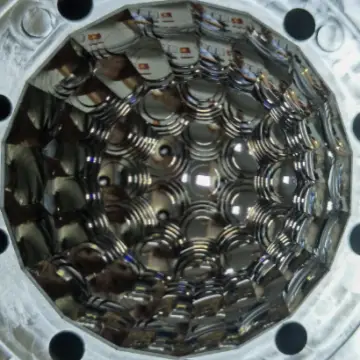

9. Master the international leading Fresnel lens processing technology to improve product performance.

10. The professional design and engineering team is responsible for the testing and evaluation of the products to ensure that the quality and performance meet the highest standards.

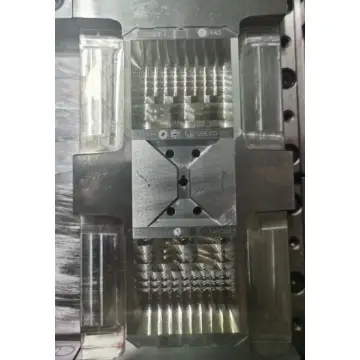

11. Mold design and fabrication of PIR sensors and optical parts is a complex process that involves knowledge in multiple areas of expertise.

Here is a brief overview:

1. Mold design:

* Determine the product size and shape: Determine the size and shape of the mold according to the specifications and requirements of the PIR sensor and optical parts.

* Choose the right material: choose the right material for manufacturing the mold, such as aluminum alloy, steel, etc.

* Design classification surface: determine the classification surface of the mold, that is, the position of the mold opening and closing.

* Design the pouring system: determine the pouring system of the mold, namely the path of molten plastic flowing into the mold.

* Design the cooling system: determine the cooling system of the mold to control the cooling speed of the plastic parts.

2. Manufacturing process:

* Rough machining: Conduct rough machining of the mold to remove the excess material.

* Finishing: refine the mold to achieve the size and shape required by the design.

* EDM: EDM for the mold to complete small, difficult machining shapes.

* Polishing: polish the mold surface to improve the surface finish.

3. Testing and commissioning:

* Size testing: Size inspection of the mold to ensure that it meets the design requirements.

* Trial mold: use the mold for trial production, and check whether the produced parts meet the requirements.

* Commissioning: debug the mold according to the mold test results to improve production efficiency and product quality.

In conclusion, the mold design and manufacturing of PIR sensors and optical parts is a complex and elaborate process that requires multifaceted expertise and skills.

Bring your product idea to life in as soon as 5 days!