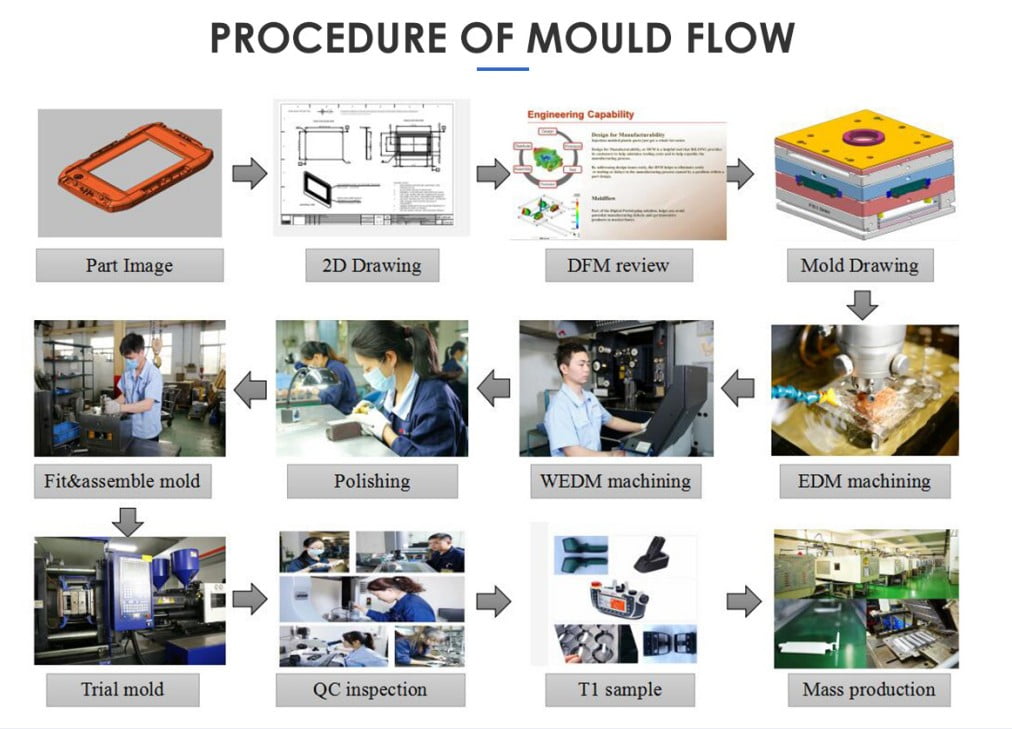

Precision mold design and manufacture

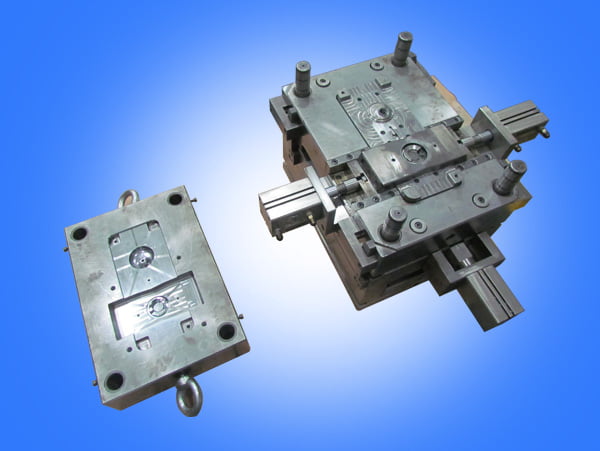

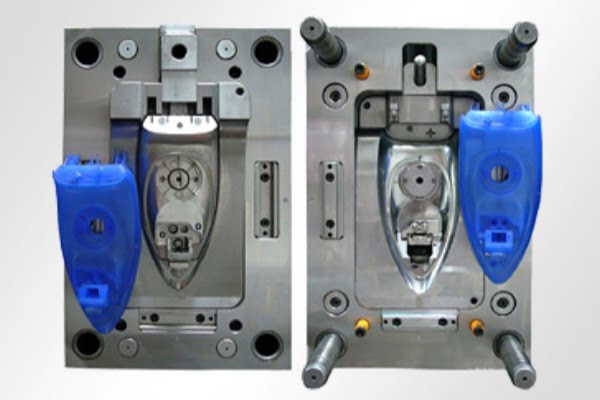

We undertake the design and manufacture of various high-precision molds, leveraging our comprehensive expertise in crafting molds for Medical, Automotive, Telecommunication, Security, consumer electronics, Sports, Musical, Marine equipment, and other industries.

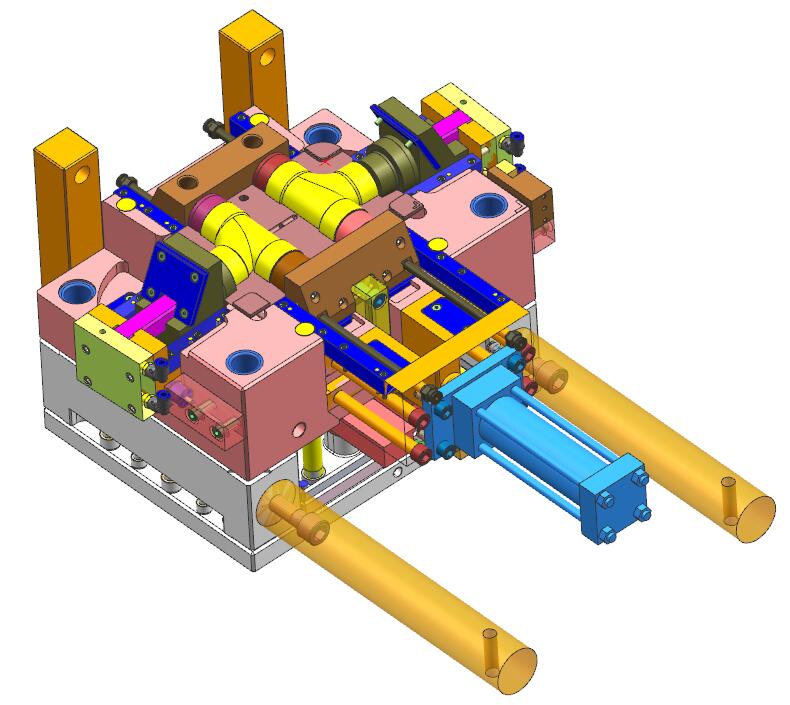

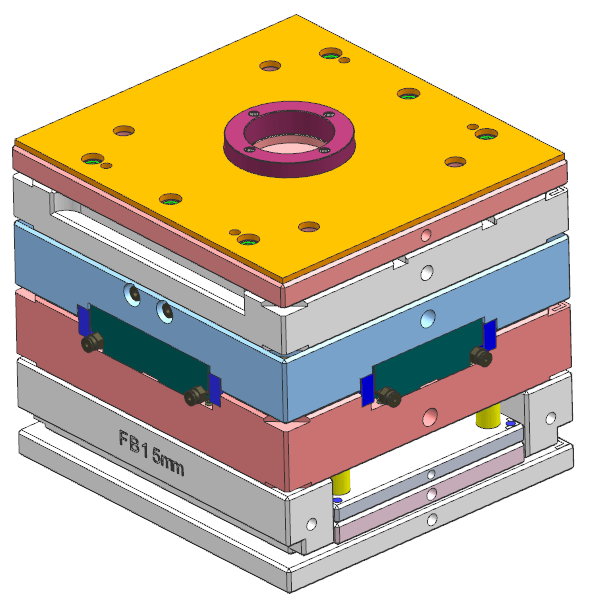

With more than30 years of experience in precision mold design and manufacturing, we can design and manufacture various types of plastic molds, rubber molds, and LSR molds; We are experts in the production of single-color injection molds, double-color and multi-material 2K injection molds & Over molds, LSR injection molds, Silicone compression molds, Flip-top cap molds, silicone keypad molds, and other silicone molds for products such as gaskets, keyboards, membrane keypad and soft medical parts.

In our mold production center, we have a variety of imported high-precision CNC machining centers, spark machines, wire cutting equipment, precision grinders, and other processing equipment, which can make sure that all of the data can be machined precisely and within the drawing spec for our customers.

The strength of our mold design and manufacturing center:

50 Experienced engineers in mold design, mold flow analysis, metal processing, and mold manufacturing. The mold precision can reach 0.005.

20000+ self-produced plastic and rubber molds making collaborating with Fortune 500 companies

30+ years OEM mold and product factory with ISO9001, ISO14001, IATF16949, 6S managing system.

Equipment owned by our mold center

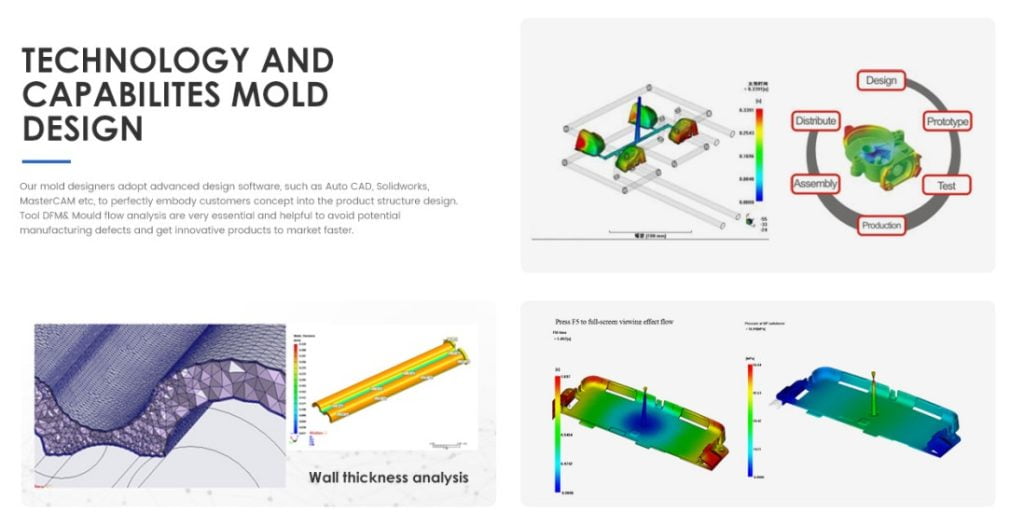

The application of mold flow analysis can meet the needs of different product development and design. Through high-speed carving and cutting (24000rpm), precision mirror discharge, and high-precision wire cutting process technology, combined with 3D CMM(Coordinate Measuring Machine), high-precision, high-quality molds are manufactured.

Production Equipment of Tooling Department

| Item | NO | Equipment Item | Brand | Quantity | Property | |||

| Tachometer/speedometer | Accuracy | MM | ||||||

| Process Equipment | 1 | CNC | ChaoQun | 1PCS | 8000/MIN | 0.01 | 850*650*900 | |

| Frank | 2PCS | 2.4W/MIN | 0.005 | 500*400*400 | ||||

| Seiki | 2PCS | 2.6W/MIN | 0.005 | 600*400*400 | ||||

| Charmilles | 1PCS | 1.4W/MIN | 0.005 | 850*650*400 | ||||

| 2 | Wire-cut machine | Wire-cut | SODICK | 1PC | 0.005 | 300*250*180 | ||

| Charmilles | 1PC | |||||||

| Speediness wire-cut | Jin teng | 1PC | 500*400*350 | |||||

| YIGUANG | 1PCS | |||||||

| YIGUANG | 1PCS | |||||||

| 3 | EDM | SODICK | 1PCS | 0.005 | 500*400*200 | |||

| SODICK | 1PCS | 0.005 | 500*400*200 | |||||

| Charmilles | 2PCS | |||||||

| XingFeng | 3PCS | 0.01 | 600*500*300 | |||||

| TaiYi | 2PCS | |||||||

| 4 | Milling machine | DaYou | 4PCS | 5000/MIN | 0.02 | 800*500*120 | ||

| Heng yu | 2PCS | 5000/MIN | 0.02 | 800*500*120 | ||||

| 5 | Grinding machine | JianDe | 3PCS | 3600/MIN | 0.002 | 450*250*300 | ||

| Hangzhou machine | 1PCS | 3600/MIN | 0.002 | 450*250*300 | ||||

| YuQing | 2PCS | |||||||

| BaoCheng | 1PCS | 3600/MIN | 0.002 | 450*250*300 | ||||

| 6 | Grinding machine | Hangzhou machine | 1PCS | 1400/MIN | 0.002 | 400*1000*300 | ||

| 7 | Turning | XingYuan | 1PCS | 1600/MIN | 0.01 | 1500*300 | ||

Bring your product idea to life in as soon as 5 days!